VOLTEC Electro Sistemes, S.L. implements the data collection system for MES (Manufacturing Execution System) in the production process of the plant that the multinational Becton Dickinson (leader of the medical sector) has in the town of Fraga (Huesca).

With this installation, Becton Dickinson achieve improved productivity and lower costs through the adoption of MES system, which allows control and monitoring of information throughout the production process in real time. Data collection is achieved by installing 120 programmable logic controllers (PLCs) to factory machines and a server that collects, integrates and analyzes optimally all the information processing controllers. This data is transferred to the company MES system.

The biggest advantage that contributes to the production system lies in being able to analyze continuously the working capacity of the machines, downtime and pace of reforms, and the identification of unemployment rates. The analysis of all information directly affects decision making, which can be done instantly.

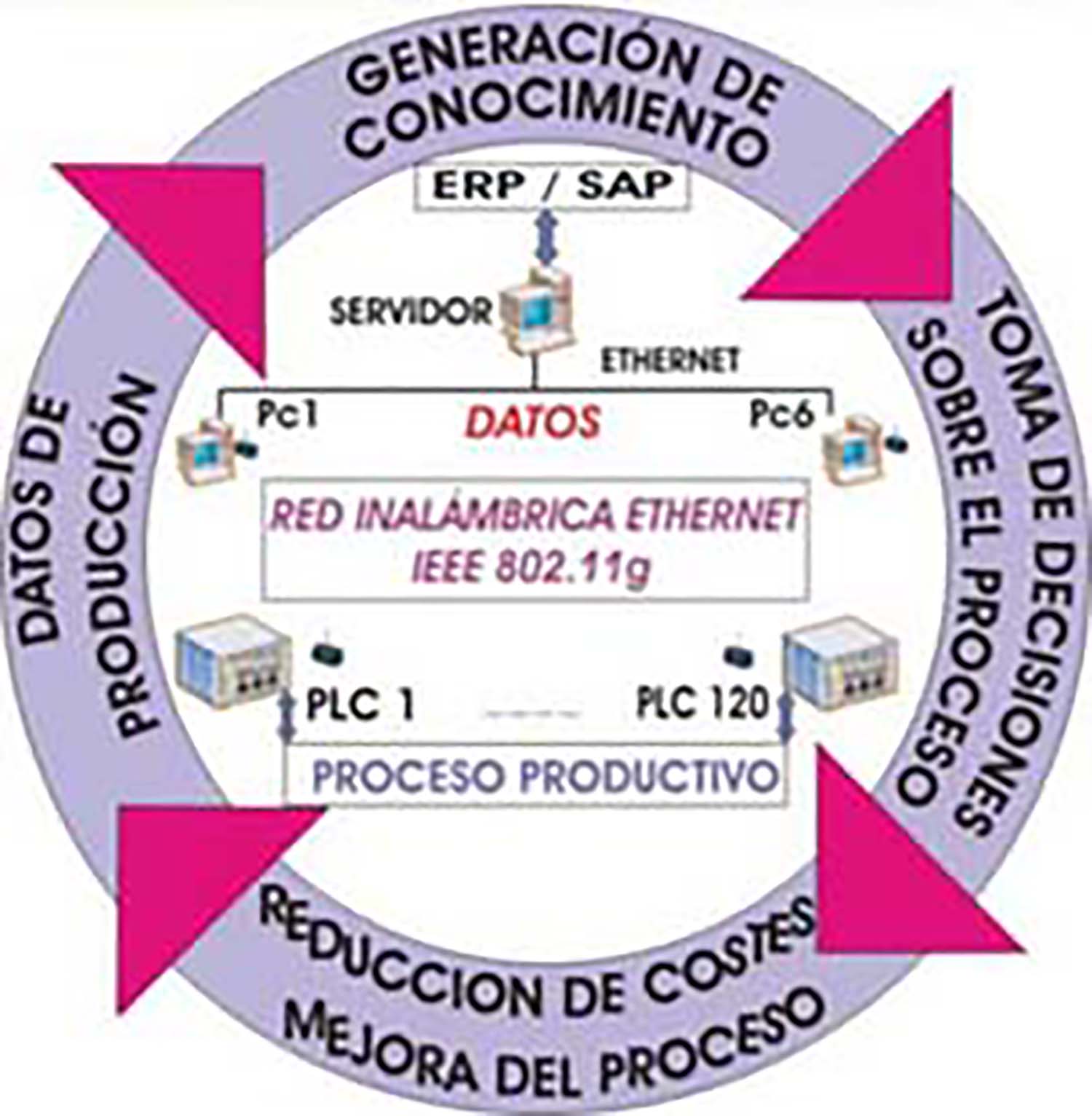

The MES system provides performance and modification of process variables in order to improve and optimize it as soon as possible by a bidirectional system. Thus, the 120 logic controllers are linked to the server via Ethernet, wireless network Wireless. The server, which processes the data from the PLC, in turn communicates with the ERP system to share information from the database.

In short, obtaining real time data allows rapid decision making, reduced response time, reduced costs and ultimately improved productivity.

WIRELESS NETWORK INSTALLATION QUICK AND ECONOMIC

The modernization of computer systems allows, in many cases, getting an optimization of the investment made by companies . Becton Dickinson has reduced the running time of the work, in addition to saving the logistical and economic problems caused by the installation of the wired network by choosing the modulated transmission wireless Ethernet (IEEE 802.11g Wireless) and solutions SAP. In addition to the mentioned advantages of wireless technology, it makes no decrease in the rate of data transmission and job success is guaranteed.