OBJECTIVE

Copinsa, with a trajectory of more than 25 years in the agro-industrial sector, is specialized in the manufacture of compound feeds, although it also has livestock integrations and agricultural exploitations. Copinsa is considering the replacement of the plant automation and control platform, as the one it had did not adequately cover a series of essential needs.

SOLUTION

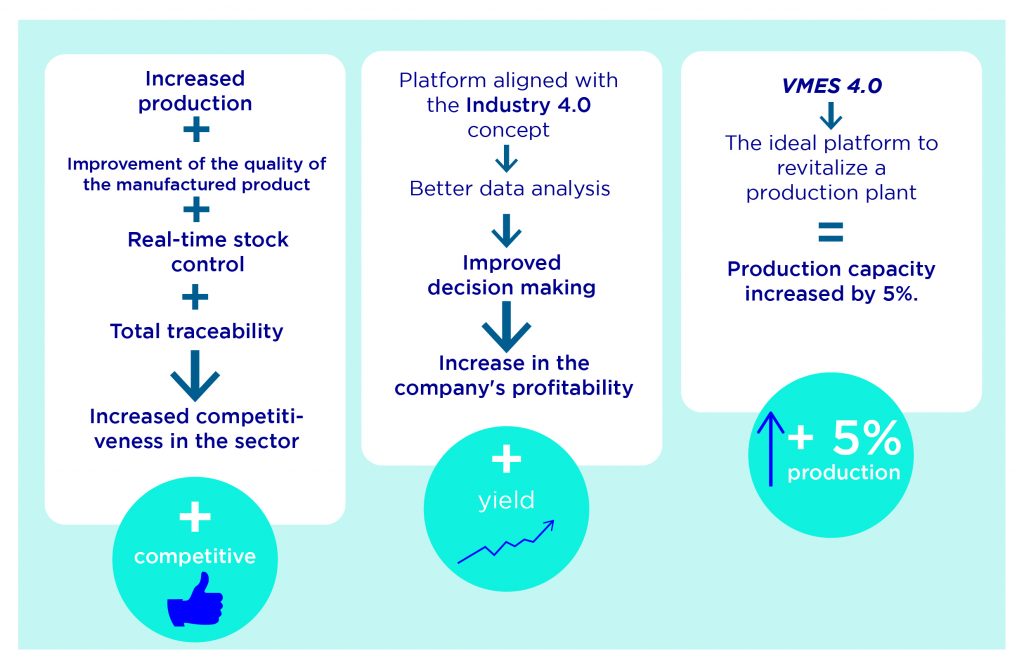

VOLTEC and its VMES4.0 are chosen by Copinsa to migrate the existing automation and control platform.

VMES 4.0 is a last generation platform, aligned with the Industry 4.0 concept, which provides a solution to the current challenges of the sector: greater food safety, stock control and traceability in real time, increase profitability, verticalize the operation of the plant…

You can learn more about the VMES4.0 solution here.

CHALLENGES

- The production plant is in operation, and the allowed downtime is minimal.

- In the company there is an ERP system (administration and finance) that must be linked to the VMES 4.0 platform (automation and control).

- The migration must be done taking into account the economic factor, trying to reuse all the elements that allow it.

- There are elements that are not controlled in a centralized way and must be integrated in the VMES 4.0 platform.

PLANNING

1. Study of the project and segmented migration. It was decided to take advantage of the power electronics, since its state allowed it, which reduced costs in time (minimum plant stops) and economic.

2. Personalized development of the link between the ERP system and the VMES4.0 system, bringing together the entire operating cycle of the company, both administrative and productive. We avoid duplication of data, increase the quantity and quality of information provided to management, streamline daily work and increase synergies between departments.

3.Scattered elements were integrated in the VMES 4.0 platform, centralizing the control in a single platform, providing greater security in the operation and making the whole operation profitable. Example: the integration of the disinfection arc controlled with RFID cards; increasing the biosecurity of the transport, since we can force the trucks to be disinfected before proceeding with the loading of feed.